0731-55672999

xiao12666@163.com

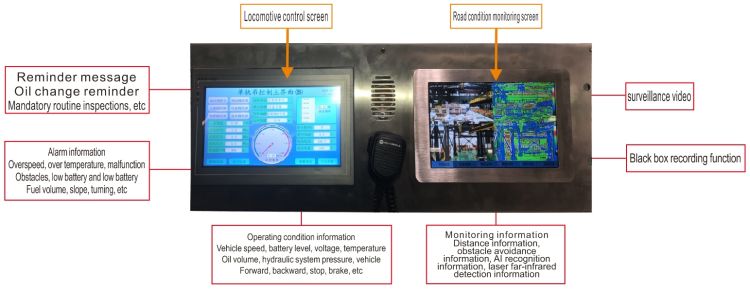

Eleven major control systems

1 Locomotive control system

1.1 It has various alarm information display functions;

1.2 It has reminder display functions such as oil change, low battery, and routine inspection;

1.3 Equipped with black box data recording function;

1.4 It has the function of displaying operating condition data;

1.5 adopts dual explosion-proof display screens, with one recording driving parameters and alarm information, and the other displaying video surveillance information;

1.6 It has the functions of displaying distance information, obstacle avoidance information, and AI recognition information.

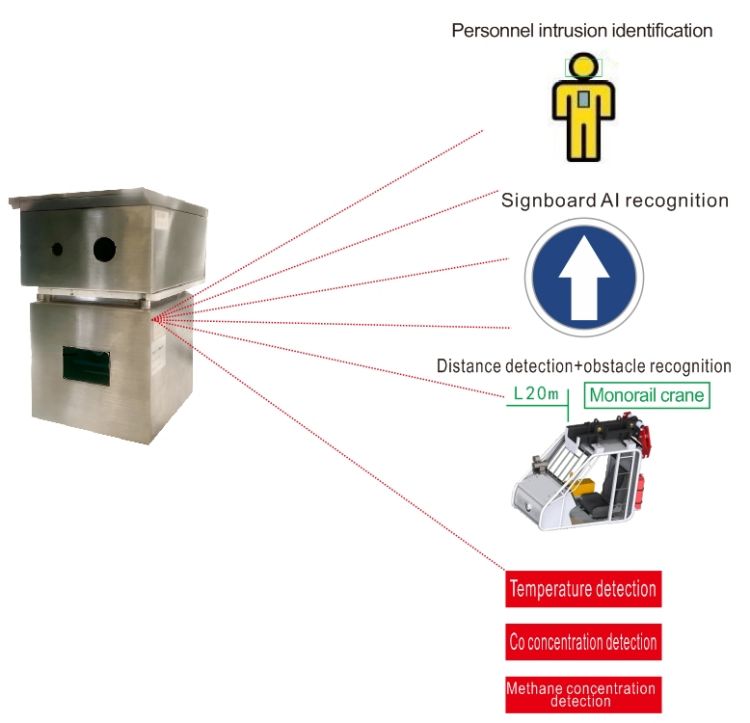

2 Road condition monitoring system

2.1 Equipped with radar distance detection function for obstacles, pedestrians, etc;

2.2 Through the intelligent recognition function of AI and LiDAR, monitor abnormal road conditions such as turning, abnormal opening and closing of switches, and calibrated signs, and alarm and stop in case of abnormalities;

2.3 It has functions such as strong light suppression, motion detection, electronic fence, wide dynamic range, digital noise reduction, and wireless transmission;

2.4 Equipped with video monitoring functions for the driver's cab and ground control room;

2.5 has temperature detection, CO concentration detection, and methane concentration detection functions.

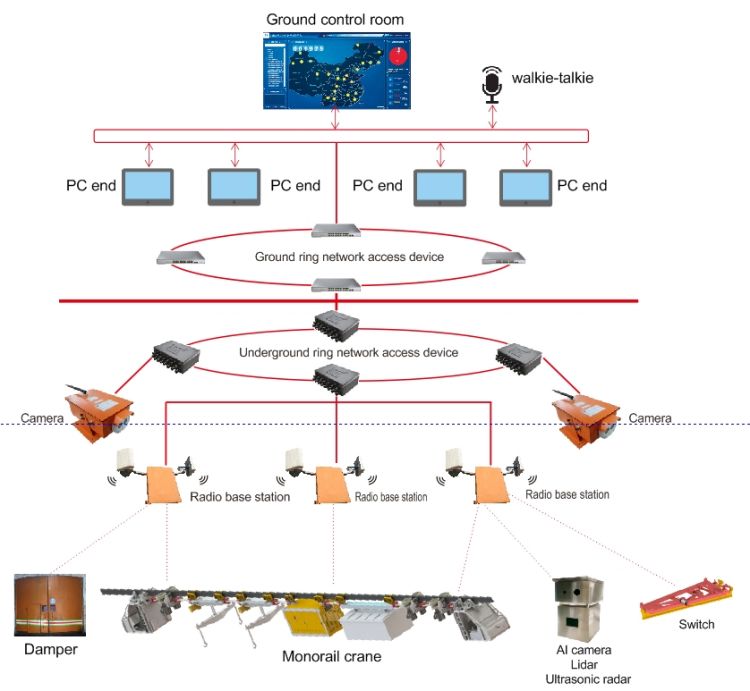

3 intelligent dispatching system

3.1 Equipped with automatic path planning function for underground transportation equipment in mines;

3.2 Equipped with intelligent scheduling function for underground transportation equipment in mines;

3.3 Equipped with remote control function for underground transportation equipment;

3.4 Equipped with switch and damper linkage control function;

3.5 has wireless transmission functions for video data and monitoring data.

4 Turnout driver control system

This device consists of all or part of components such as a controller, remote control, switch display box, sensor, and actuator (cylinder).

Equipped with underground remote control lifting, turnout remote control turning, and locomotive remote control driving functions, with a remote control distance of 50m.

4.1 The controller adopts a microcontroller with strong anti-interference ability to recognize wireless remote control signals, and can remotely control the turnout;

4.2 Adopting digital coding technology, the system has strong anti-interference ability;

4.3 The display box intuitively indicates the working status of the turnout device, with high brightness and beautiful font;

4.4 The device has a small volume, simple installation, and easy operation.

5 Remote control system

Equipped with underground remote control lifting, turnout remote control turning, and locomotive remote control driving functions, with a remote control distance of 50m.

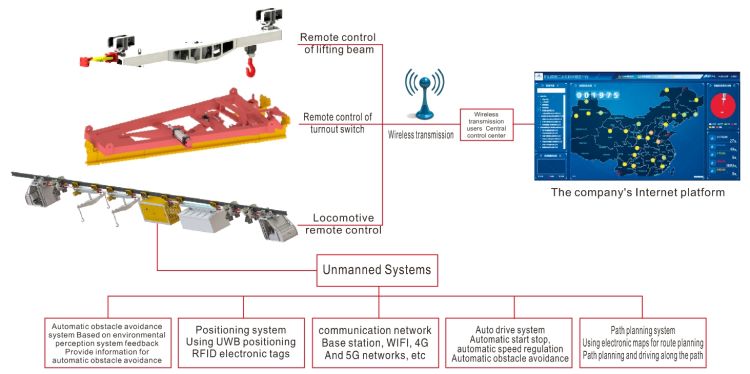

6 Unmanned Systems

6.1 Video, audio, and operational data of locomotive operation can be uploaded to the user's ground control room or our company's industrial interconnection

The functions of the network intelligent control platform;

6.2 Equipped with remote operation functions such as lifting beams and turning turnouts;

6.3 Equipped with unmanned monorail crane driving function

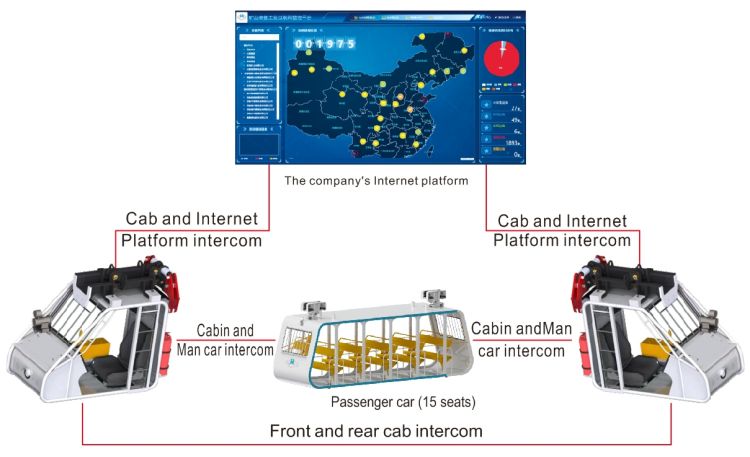

7 Locomotive intercom system

It has the function of voice intercom between the front and rear cabins, passenger cars, and ground control rooms.

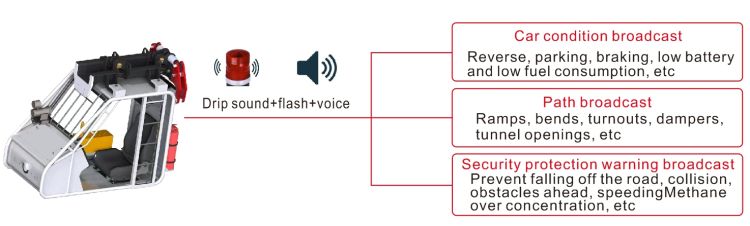

8 Voice alarm system

8.1 Equipped with vehicle condition broadcasting functions such as reverse, parking, braking, and starting operation;

8.2 It has the function of broadcasting road conditions such as ramps, bends, turnouts, air dampers, and tunnel entrances;

8.3 Broadcast the top 15 safety protection warnings, including anti falling, collision, obstacles ahead, speeding, and methane concentration exceeding;

8.4 There is a beep and flash function accompanying the voice alarm.

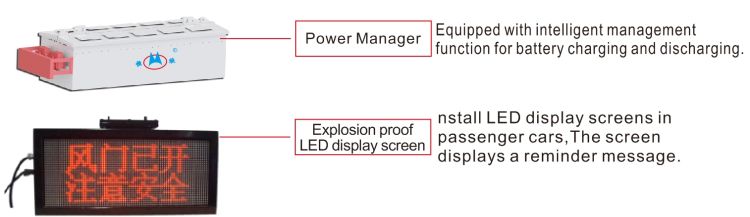

9 Power management system and LED display screen

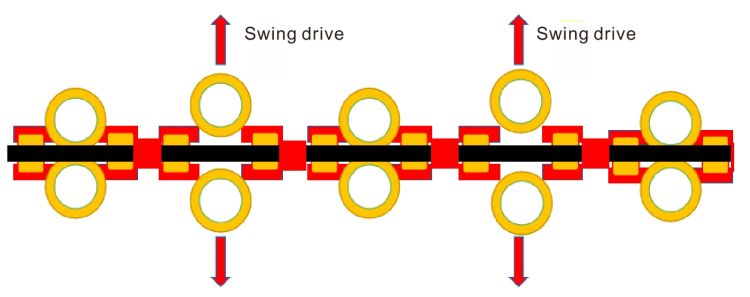

10 Intelligent swing drive system

By controlling the clamping oil cylinder to loosen the two drive wheels clamped on the track on the driving part, swing drive is achieved. By controlling the set number of driving parts to swing drive, energy and material consumption are reduced.

Free grouping: By reasonably distributing the power of the driving part, it is possible to group between two to fourteen drives to achieve efficient transportation of monorail cranes.

Efficiency improvement and growth rate: During the swing drive, the two motor oil ports on the drive unit are simultaneously disconnected from the oil volume of the drive system, which can improve the transportation speed.

11 distributed control system

Copyright Copytight 2024 © Xiangtan Hengxin Industrial Co., Ltd Address:Hunan Shaoshan High tech Industrial Development Zone Record number:湘ICP备11000497号-1

business license Technical Support:Jingwang Zhiying