0731-55672999

xiao12666@163.com

The ZR127 (A) mining overhead passenger electric control device adopts an imported PLC programmable controller, and has two information display functions.

Product Introduction

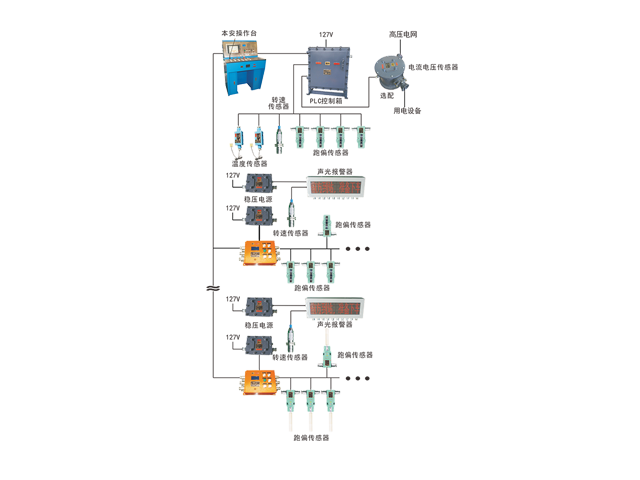

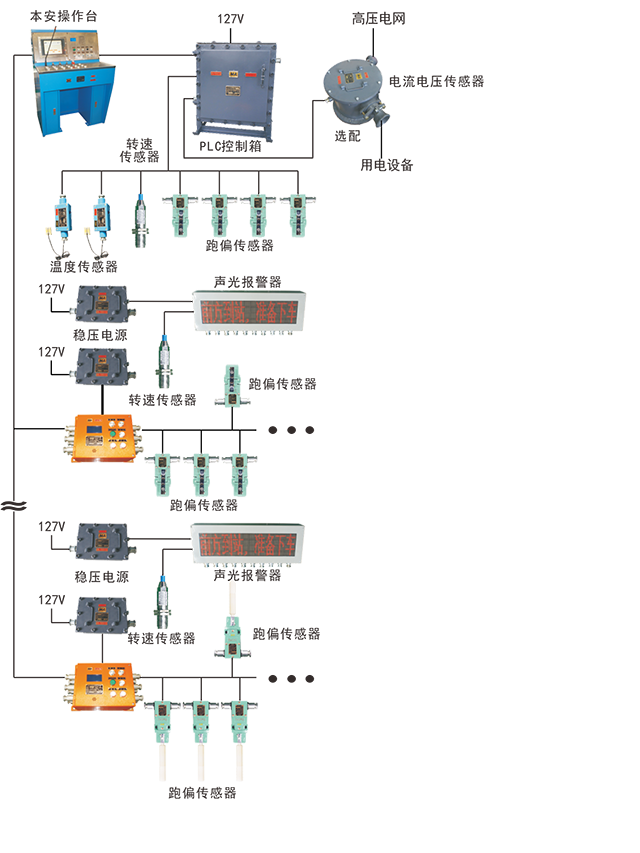

3 Device Structure Diagram

Copyright Copytight 2024 © Xiangtan Hengxin Industrial Co., Ltd Address:Hunan Shaoshan High tech Industrial Development Zone Record number:湘ICP备11000497号-1

business license Technical Support:Jingwang Zhiying