0731-55672999

xiao12666@163.com

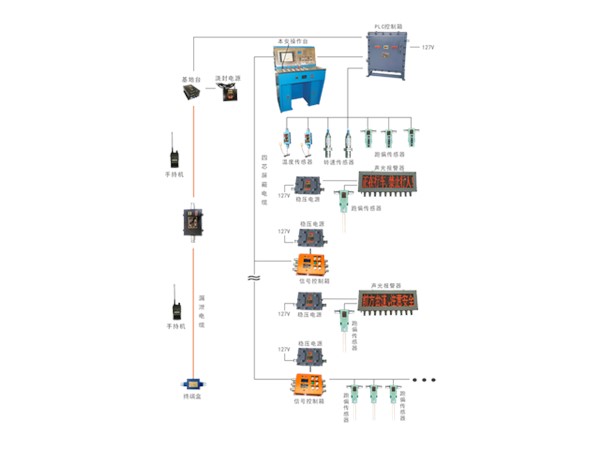

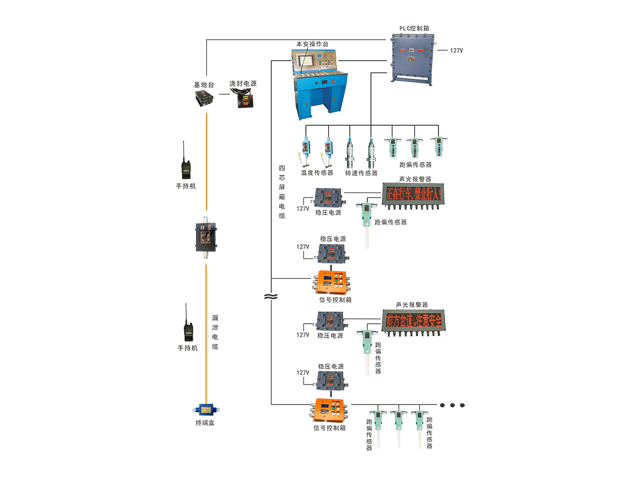

The ZJK127 (A) mining endless rope winch control device is suitable for the protection and control of underground endless rope winch transportation in coal

Product Introduction

Copyright Copytight 2024 © Xiangtan Hengxin Industrial Co., Ltd Address:Hunan Shaoshan High tech Industrial Development Zone Record number:湘ICP备11000497号-1

business license Technical Support:Jingwang Zhiying